If a boiler powers your home’s heating system, then warm water flowing through radiant floors, hydronic baseboard heaters, radiators, or even valance heating on the ceiling warms the interior space. Hydronic heat is common in decades-old Eichler homes as well as in newer houses. It uses less space than forced air -- the 3/4-inch-diameter copper or PEX tubing employed carries the same heat energy as an 8x14-inch sheet-metal duct in a forced-air system. Radiant floors themselves are essentially invisible heating appliances, and they are especially effective at warming people in high-ceilinged rooms.

Boilers in California are almost always powered by natural gas, but hydronic heat can be electrified with an air-to-water heat pump.

This gas-powered boiler was replaced with an efficient electric air-to-water heat pump.

If you have a hydronically heated home and your boiler is aging, or you are interested in adding some cooling to your house, consider replacing your boiler with an air-to-water heat pump. These efficient electric appliances extract heat (or cold) from the air using a refrigerant, then warm (or cool) the circulating water with that heat. Air-to-water heat pumps are used in Europe and Asia and increasingly in the US, even in the cold northeast. California’s building code recently recognized just how efficient they are, which is starting to drive more adoption. The temperate Bay Area is a particularly easy place to configure an air-to-water heat pump. I have had one for over two years and it’s been great at both heating and cooling the house.

A Chiltrix air-to-water heat pump sits outside a home.

These heat pumps have two components, a large external box with a fan that goes outside of the house and a buffer tank that goes inside. The outside box contains the elements needed to warm (or cool) the water that will circulate through the house as well as those to warm (or cool) the refrigerant. (1) Indoors, a passive buffer tank connected to the outside unit helps the system run more efficiently (at a slow, steady pace) by acting as a thermal battery. Tanks vary in size, but 20-40 gallons is common. The tank will typically be placed where your boiler is since it will have many of the same connections.

A larger buffer tank makes for more efficient operation, which saves electricity. The one shown is 37 gallons. These tanks have hookups for electric resistance elements for backup heat if you live in a colder environment.

Inside the home there are a number of ways to use the water from the buffer tank to condition your space. Most common is a radiant floor. Air-to-water heat pump systems work seamlessly with radiant floors as long as the temperature used to heat the floor is no more than about 110F. Many of these air-to-water heat pumps cannot heat water above 120F.

This 104F temperature is in the sweet spot for many air-to-water heat pumps.

If your boiler is set to 110 or less, then you can use a reversible heat pump like those made by Aermec, Chiltrix, and SpacePak. These provide cooling as well as heating. Cooling can work with few changes if you have a radiant floor. In our arid area, we don’t have to worry much about condensation on a cool floor, though controls are available that will raise the temperature of the circulating water when needed. (2) There are also products on the market -- air-emitting fan coils and radiant convectors -- that provide efficient and quiet cooling (and heating) when paired with a heat pump. They can be mounted on walls high or low, freestanding on floors, or hidden in soffits, under floors, or behind walls.

Jaga offers a variety of low-temperature convectors. Source: Jaga

If your boiler is set to a higher temperature, it may be because you have heaters in the home that are designed for high temperature water, such as cast iron radiators. Or it could be because your radiant floor has aged and become less effective so the temperature has been increased to compensate. If you switch to a low-temperature heat pump, you can replace older heaters or supplement an aging floor with the emitters mentioned above, which are designed for lower temperature water and provide both heating and cooling. Alternatively, there is a heat pump made by Harvest Thermal that does put out higher temperature water, though it can be tricky to get it working well with radiant floors. (3) This heat pump is not reversible, so it provides heating but not cooling. On the plus side, it can handle your domestic hot water at the same time. Chiltrix says it is coming out with a reversible high-temperature air-to-water heat pump soon.

In my house, a reversible heat pump warms radiant floors in winter and cools them in summer. I installed two behind-the-wall fan coils for additional cooling in the common rooms. (4) A Nest thermostat in that area is configured for multistage heating and cooling to control both the floor and fan coils. The heat pump itself is on the small side for a 2100 sf home, providing 2.8 tons of heating and 2 tons of cooling, but it works fine for the well-insulated home. On the coldest days when the unit runs less efficiently because it has to work harder to extract heat, I find that it helps to close off the large master bedroom, which is a heat sink with its high ceiling, large panes of glass, and poorly insulated roof.

This Nest thermostat is set to two-stage heating and cooling to manage both the radiant floor and the fan coils in the common areas. The two-stage setup is shown on the left, while the heating and cooling options are shown on the right. In other areas where only a radiant floor is available, the thermostat is configured for standard (single-stage) heating and cooling.

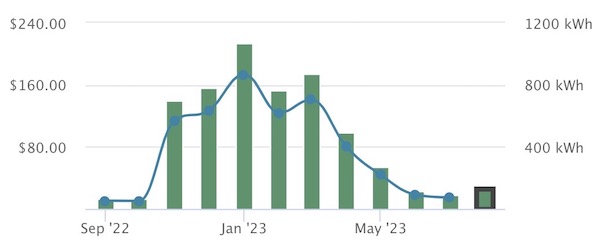

This past winter, which was a cold winter for the Bay Area, the system used between 630 and 870 kWh per month, as measured by a circuit monitor I have installed. The cost for the power, from $155 to $215 per month at the new Tier 2 prices ($.25/kWh in Palo Alto), is similar to what I would pay for gas here, the equivalent being around 65-85 therms. The installation cost was around $25,000 for the radiant conversion, plus an extra $5,000 for two fan coils, which were optional. The conversion was not cheap, and may not get cheaper for a while due to lack of qualified installers.

This chart shows the power used and cost of running my air-to-water heat pump this past year. Billing is shown as green bars (see left axis) and power consumption as a blue curve (see right axis). The chart assumes electricity costs of $.25/kWh, the new Tier 2 Palo Alto rate. Source: Eyedro circuit monitor

In fact, the most difficult part of these conversions is probably finding a skilled contractor. Replacing a gas-based hydronic system with an electric one requires plumbing skills, HVAC skills, and some electrical know-how. More experienced installers will do a cleaner and more efficient installation by insulating pipes carefully to conserve heat, reducing bends in piping to conserve pressure, sizing appropriately for ample but efficient heating and cooling, and so forth. These conversions take time and there are not enough tradespeople to go around. One hydronics expert I spoke with is looking to design drop-in replacements for some common configurations, which could make retrofits faster and more scalable. But because his schedule is so busy, he is having trouble finding the time to do the necessary engineering.

I would also add that this technology can be finicky. In researching this blog, I found that for the last few months my heat pump has been drawing 100 watts even when it is idle. Diagnostics indicate that the water pump is not turning off, so I’m waiting on tech support to help with it. I do recommend installing an inexpensive circuit monitor with these power-intensive, variable speed appliances in order to better understand how much power they are using and why.

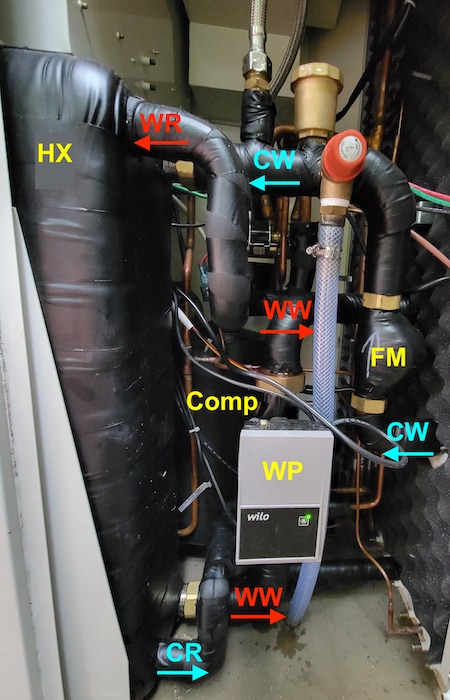

A peek inside

For those who are interested in seeing the innards of one of these appliances and learning a bit more about how they work, here are a few pictures.

This Chiltrix heat pump has most of its equipment in a compartment on the right. The left side consists of a fan and a large coil heat exchanger. Both are described below.

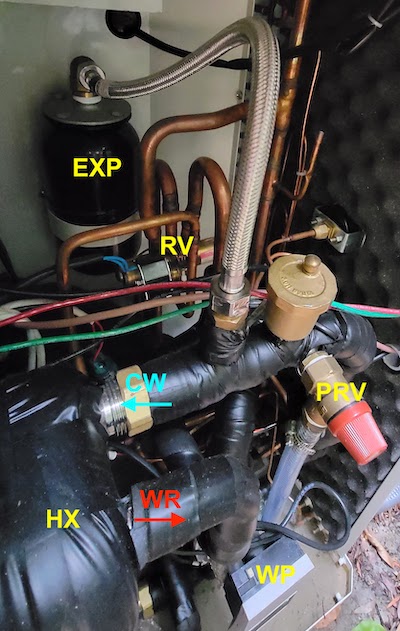

If you open the side of the box that faces to the right, you see this. The important components in the photo above are the large heat exchanger (HX), the compressor (Comp), and the water pump (WP). The plate heat exchanger takes as input (at the top) cold water (CW) and warm gas refrigerant (WR), and outputs at the bottom warm water (WW) and cold liquid refrigerant (CR). A water pump (WP) moves the warm water back to the house, while also pulling cold water from the house. A compressor (Comp) powers the refrigerant cycle. The cold refrigerant leaving the plate heat exchanger travels to a large thin coil heat exchanger wrapping the inside of the box (see photo below), where a fan pulls air over the exchanger to warm the refrigerant. The refrigerant then goes back through the compressor and into the heat exchanger as a warm gas. The compressor uses most of the power in this box, though the water pump also uses some. The power to each is automatically adjusted as needed, saving energy. The photo above also shows a flow meter (FM) on the water circuit. In the middle of the photo, unlabeled, is the reversing valve that can switch this appliance between heating and cooling.

The higher angle in this photo shows an expansion tank (EXP) in back, the reversing valve (RV) in front of it, and a pressure release valve (PRV) for the water circuit.

If you open the right side of the front of the box, you see the control board on the top, the inverter board lying flat above it, and the compressor wrapped in a cover below. The control board makes adjustments to pump and compressor speeds based on multiple inputs. The inverter board manages power to the unit.

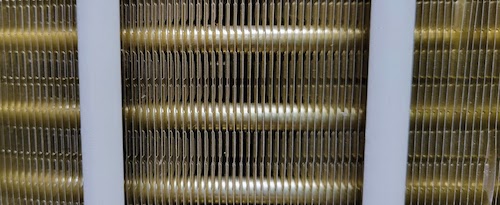

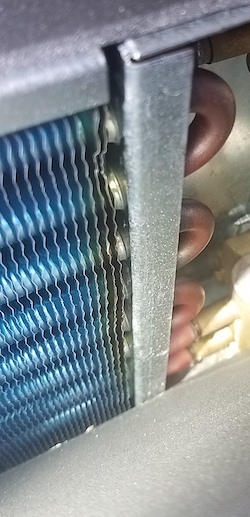

The entire left part of the box consists of a large finned-tube coil heat exchanger. The refrigerant tube wraps through it and the fan draws air over the exchanger so the refrigerant can warm up (or cool down) as needed. Tiny fins effectively extend the surface area of the long and winding refrigerant tube, enabling it to better capture heat from the air blowing across it.

The garage-mounted fan coils have a similar finned tube coil heat exchanger. Both have a fluid (refrigerant or water) exchanging heat with the air. In the case of the garage-mounted exchanger in the fan coil, the goal is to heat or cool the air passing over it. In the case of the outdoor coil in the heat pump, the goal is to heat or cool the refrigerant inside the coil. But both air and fluid change temperature during these heat exchanges.

Congrats on making it this far! Please share any comments or questions you have about these air-to-water heat pumps in the comments section below.

Notes and References

00. Email notifications for this blog have not been working for several months, but I think they are working now. Please lmk if you are having any problems being notified when a new one is available. Update; Argh, I think they're still not working.

0. I’d like to thank my HVAC contractor for reviewing this blog post.

1. These all-in-one systems are meant to be easier to install, partly because they keep the refrigerant enclosed in one outdoor box. However, there are also split systems with an outdoor unit that captures heat from the air (so it has a fan, an outdoor coil, and a compressor), and an indoor unit that transfers the heat to the water (so it has a heat exchanger and water pump, plus the electronics). These require refrigerant to be piped between the two systems. You can read more about different configurations in this helpful writeup.

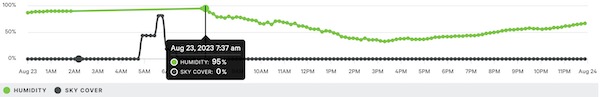

2. I have used a radiant floor for occasional cooling for two years with no sign of condensation. However, it’s possible that with the changing climate we will see more frequent high dew points in coming years. When air has a higher moisture content, water condenses at warmer temperatures. More tropical storms could mean that a floor surface cooled down to 65F would be more likely to experience condensation. On August 23 this year, humidity hit 95% in Palo Alto, and we had a dew point of nearly 70 a few hours later.

Humidity was 95% at 7:37am on August 23 in Palo Alto. Source: KCAPALOA199 Personal Weather Station

The dew point was 69.7F at 11:27am on August 23 in Palo Alto. Source: KCAPALOA199 Personal Weather Station

3. Harvest Thermal uses the Sanden heat pump, which is designed for domestic hot water. It is a terrific hot water heater, with an outdoor component and an indoor component. The Sanden uses carbon dioxide as a refrigerant, which has much less warming impact than standard refrigerants. But CO2-refrigerated systems work best when the fluid coming (back) into the heat pump is much cooler than the fluid leaving. That is true for domestic hot water (the incoming fluid is just cold water). But radiant floors typically don’t drain that much heat out of the circulating fluid -- if they did, the rooms at the end of the radiant loop wouldn’t get heated properly. So some contractors report difficulty getting these systems to provide enough radiant heat. The systems work better if hot water is running. In Europe with similar systems they sometimes reverse the direction of the heat pump circuit every 30 minutes, so that every room is on the warm side of the circuit each hour.

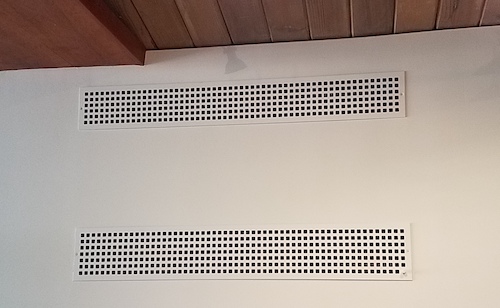

4. The fan coils were more of an experiment than anything else. The two common rooms are both adjacent to the garage where the HVAC closet is, so the location was convenient. Connections could be short and simple, plus there was a nice way to mount the fan coils behind the walls (i.e., in the garage) so only a grill would be visible from inside the house. In addition, the kitchen area has no radiant floor, so the fan coils provide extra value. It turns out that the air cooling is really nice in these rooms on hot days, but I’m not sure it was worth the cost and effort to put the fan coils in.

From inside the house the vents look like this, with the intake on the bottom and the outflow on top.

The garage side looked like this midway through construction. The contractor had to build a fireproof box to go around the fan coil because it penetrates the drywall.

Current Climate Data

Global impacts (July 2023), US impacts (July 2023), CO2 metric, Climate dashboard

Comment Guidelines

I hope that your contributions will be an important part of this blog. To keep the discussion productive, please adhere to these guidelines or your comment may be edited or removed.

- Avoid disrespectful, disparaging, snide, angry, or ad hominem comments.

- Stay fact-based and refer to reputable sources.

- Stay on topic.

- In general, maintain this as a welcoming space for all readers.